CASE STUDY:

Sauces, Dressings & Dips

Pump:

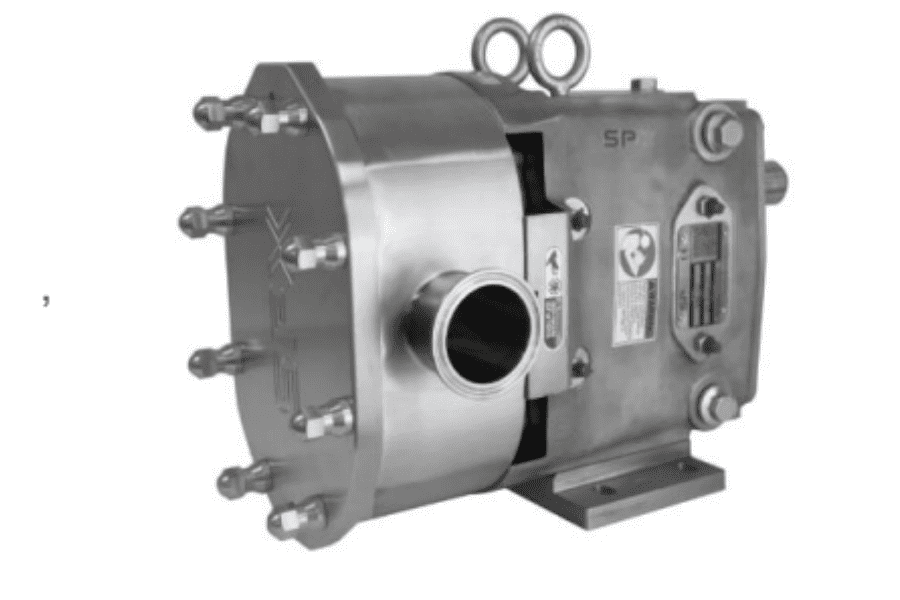

Universal 3 Series Positive Displacement Pump

Industry /Application:

A major processor of sauces, dressings and dips uses positive displacement (PD) pumps to transfer its products that contain suspended particulates such as tomato, onion, pepper pieces, garlic, basil and salt.

Problem:

The customer* had been using PD pumps in their process lines for many years. However, after a period of time, they discovered small ingredient particulates beginning to accumulate around the cover O-ring even after completing the clean in place (CIP) cycles giving rise to a risk of contamination. Sanitation personnel were then forced to open and further clean the pumps manually (on designs meant to be fully CIP-able) – delaying production times significantly.

Solution:

The customer tested a Waukesha Universal 3 PD Pump that utilizes a L-shaped gasket in the front of the body which mates up with the flat pump cover, preventing particles from accumulating. The customer ran multiple test products and CIP solution through a model U3 size 045. After each run, the pump was disassembled for inspection and no accumulation around the L-gasket was found.

Result:

The customer was delighted with the results and has informed SPX FLOW that they are making plans to replace other pumps with the Waukesha Universal 3 series. As an additional benefit, U3 pumps use the same shaft seals for model sizes 30-130, helping to further reduce spare parts inventories.

Interested in learning more about our solutions?

What Our Customers Have to Say…

“LPE has been a reliable partner for many years. They have the ability to support our business through their vast inventory of replacement pumps, repair components, and their service & repair center in Kaukauna, WI. LPE has offered proactive support by carrying safety stock of complete pumps at their facility to support our specific production needs.”

Operations Manager – Food Processing Facility

“We have a great relationship with LPE as they provide exceptional technical expertise for sizing and specifying pumps and valves for our process equipment needs. LPE’s customer service and response time on quotes is industry leading.”

Process Engineer – Beverage Production Company

“LPE will put in the time and effort up front to fully comprehend complex processes, resulting in a system that meets, and frequently surpasses expectations.”

Head of Procurement – Chocolate Production Company

“The LPE Team has a great understanding of fluids-based process equipment. They are a valuable resource in the design and development of the solutions we offer our customers. The LPE Team helps us to design and build better solutions for our customers.”

Design Engineer – Process Equipment Integrator

“LPE has been a reliable partner for many years. They have the ability to support our business through their vast inventory of replacement pumps, repair components, and their service & repair center in Kaukauna, WI. LPE has offered proactive support by carrying safety stock of complete pumps at their facility to support our specific production needs.”

Operations Manager – Food Processing Facility

“We have a great relationship with LPE as they provide exceptional technical expertise for sizing and specifying pumps and valves for our process equipment needs. LPE’s customer service and response time on quotes is industry leading.”

Process Engineer – Beverage Production Company

“LPE will put in the time and effort up front to fully comprehend complex processes, resulting in a system that meets, and frequently surpasses expectations.”

Head of Procurement – Chocolate Production Company

“The LPE Team has a great understanding of fluids-based process equipment. They are a valuable resource in the design and development of the solutions we offer our customers. The LPE Team helps us to design and build better solutions for our customers.”

Design Engineer – Process Equipment Integrator