CASE STUDY:

Ground Beef

Pump:

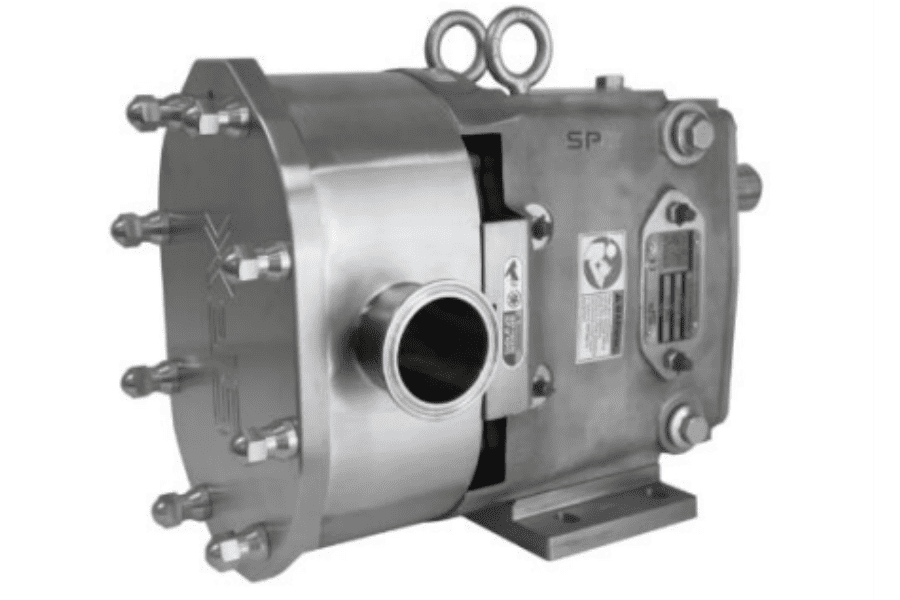

Universal 3 Series Positive Displacement Pump (U3)

Industry / Application:

A food plant receives bulk quantities of ground beef, cooks and re-packages it for distribution to restaurants in a major fast-food chain. This process involves gently pumping the cooked ground meat to a package filling machine while maintaining product texture. Hot grease from the cooked meat acts as a carrier fluid for the pumping process.

Problem:

The Customer’s* plant had been using Positive Displacement (PD) pumps to pump the ground beef, but the meat started packing behind the pumps’ rotor hubs which squeezed the hot grease carrier fluid out of the beef. Over time, the beef became harder and harder and eventually broke the pump seals. Although the pumps were designed for CIP cleaning, manual intervention was regularly required to disassemble and clean the meat away from the rotor hubs, reducing production runtimes and adding unacceptable maintenance overheads to the process.

Solution:

SPX FLOW design engineers created a rotor with ‘flats’ on each side of the hub on a Waukesha Universal 3 PD Pump to improve circulation behind the rotor hubs. The U3 has tight clearances to pump the low viscosity hot grease along with the ground beef and its large rotor cavities provide gentle pumping to preserve the texture and characteristics of the meat. The processor installed the modified rotor into a U3 size 130 pump which proved to stop the build up of meat behind the rotor hub. The rotors with flats were subsequently installed in three additional pumps in the Customer’s plant which have been running trouble-free and cleaning very well during CIP cycles. Front loading seals on the pumps further helped reduce maintenance times.

Interested in learning more about our solutions?

What Our Customers Have to Say…

“LPE has been a reliable partner for many years. They have the ability to support our business through their vast inventory of replacement pumps, repair components, and their service & repair center in Kaukauna, WI. LPE has offered proactive support by carrying safety stock of complete pumps at their facility to support our specific production needs.”

Operations Manager – Food Processing Facility

“We have a great relationship with LPE as they provide exceptional technical expertise for sizing and specifying pumps and valves for our process equipment needs. LPE’s customer service and response time on quotes is industry leading.”

Process Engineer – Beverage Production Company

“LPE will put in the time and effort up front to fully comprehend complex processes, resulting in a system that meets, and frequently surpasses expectations.”

Head of Procurement – Chocolate Production Company

“The LPE Team has a great understanding of fluids-based process equipment. They are a valuable resource in the design and development of the solutions we offer our customers. The LPE Team helps us to design and build better solutions for our customers.”

Design Engineer – Process Equipment Integrator

“LPE has been a reliable partner for many years. They have the ability to support our business through their vast inventory of replacement pumps, repair components, and their service & repair center in Kaukauna, WI. LPE has offered proactive support by carrying safety stock of complete pumps at their facility to support our specific production needs.”

Operations Manager – Food Processing Facility

“We have a great relationship with LPE as they provide exceptional technical expertise for sizing and specifying pumps and valves for our process equipment needs. LPE’s customer service and response time on quotes is industry leading.”

Process Engineer – Beverage Production Company

“LPE will put in the time and effort up front to fully comprehend complex processes, resulting in a system that meets, and frequently surpasses expectations.”

Head of Procurement – Chocolate Production Company

“The LPE Team has a great understanding of fluids-based process equipment. They are a valuable resource in the design and development of the solutions we offer our customers. The LPE Team helps us to design and build better solutions for our customers.”

Design Engineer – Process Equipment Integrator